Article of the Month - October 2024 |

This article in .pdf-format (9 pages)

The construction industry is undergoing a significant transformation as it strives to meet the challenges of sustainable development. In Malaysia, the emergence of the "all construction performer" is playing a pivotal role in driving sustainable construction practices. This comprehensive approach integrates various construction roles and advanced technologies, setting new benchmarks for efficiency, innovation, and environmental responsibility. The "all construction performer" concept refers to a holistic approach where multiple construction roles and functions are seamlessly integrated to optimize project delivery. This model emphasizes collaboration, continuous learning, and the use of advanced technologies, such as the Internet of Things (IoT), to enhance construction processes. By breaking down traditional silos and fostering a collaborative environment, the all construction performer aims to achieve higher levels of efficiency, reduce waste, and promote sustainable practices.

The Role of IoT in Sustainable Construction

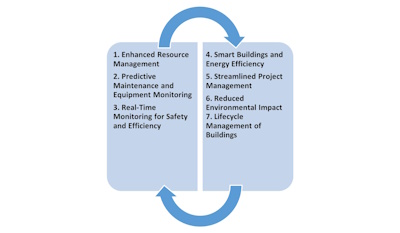

The Internet of Things (IoT) is transforming industries worldwide, and the construction sector is no exception. In the context of sustainable construction, IoT offers numerous benefits that can enhance efficiency, reduce resource consumption, and improve overall project management. By leveraging interconnected devices and real-time data, IoT can drive the construction industry toward more sustainable practices while increasing productivity and lowering costs. Figure 1 shown the list of benefits of IoT towards Sustainable Construction.

Figure 1: The benefit of IoT in Sustainable Construction

One of the primary benefits of IoT in construction is its ability to optimize resource usage. Smart sensors and connected devices can monitor real-time energy consumption, water usage, and material quantities on construction sites. This data allows for better decision-making, helping construction managers reduce waste, limit excess ordering, and ensure that materials are used efficiently. Additionally, IoT-enabled systems can track the carbon footprint of construction activities, ensuring that projects align with environmental sustainability goals.

IoT also plays a vital role in maintaining construction equipment and machinery. Through IoT-enabled sensors, construction firms can monitor the performance of machinery and detect any malfunctions or inefficiencies before they lead to costly breakdowns. Predictive maintenance powered by IoT reduces downtime, extends the lifespan of equipment, and cuts down on unnecessary energy consumption, contributing to more sustainable operations.

Safety is a significant concern in the construction industry, and IoT can improve both worker safety and operational efficiency. Wearable IoT devices for workers can monitor their health, location, and working conditions, ensuring that they are operating in safe environments. Furthermore, real-time monitoring of site conditions, such as temperature, humidity, and air quality, helps to create a healthier work environment, while also optimizing the use of climate control systems, further conserving energy.

IoT plays a critical role in the development of smart buildings that prioritize energy efficiency. Sensors and IoT devices can regulate lighting, heating, ventilation, and air conditioning (HVAC) systems, adjusting them according to occupancy levels and environmental conditions. This not only improves energy efficiency but also enhances the comfort of building occupants. The ability to collect and analyze data on energy usage patterns also enables designers and engineers to create more sustainable building designs.

IoT improves the overall management of construction projects by enabling real-time tracking of progress and resource allocation. Connected devices can provide updates on construction milestones, material deliveries, and workforce deployment. This allows project managers to adjust plans on the fly, reducing delays, material wastage, and cost overruns. By facilitating better coordination among teams and improving decision-making, IoT contributes to more sustainable project execution.

With IoT devices continuously monitoring and optimizing every aspect of a construction site, the environmental impact of construction projects can be significantly reduced. For example, IoT solutions can monitor pollution levels, energy usage, and emissions, ensuring that the project adheres to sustainability standards and regulations. Real-time data enables construction managers to take corrective action to minimize negative environmental effects.

Beyond the construction phase, IoT can continue to support sustainability throughout the lifecycle of a building. Smart building systems powered by IoT can track energy usage, monitor structural health, and optimize maintenance schedules. By doing so, the building's energy performance can be continuously improved, contributing to long-term sustainability and reduced operating costs.

Key Barriers to IoT Integration in Construction

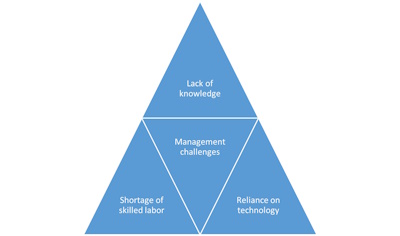

While the Internet of Things (IoT) offers numerous benefits to the construction industry, its integration faces several significant barriers. These challenges can hinder widespread adoption and limit the transformative potential of IoT technologies. Figure 2 shown the key barriers IoT integration in construction.

Figure 2: Key

barriers IoT integration in construction

Many construction professionals lack the necessary knowledge and skills to effectively implement IoT technology. The construction industry has traditionally relied on manual processes and physical labor, resulting in a workforce that may not be familiar with advanced technological tools and concepts. IoT systems involve complex networks of sensors, data analytics, and cloud computing. Without a foundational understanding of these technologies, construction professionals struggle to integrate and utilize IoT effectively. Many construction firms do not prioritize or invest in continuous education and training programs that cover emerging technologies. This results in a skills gap where existing employees are unprepared to handle new tech advancements. Older professionals, in particular, may be resistant to learning new technologies due to comfort with established methods. This generational gap in technology adoption further exacerbates the knowledge deficit. Without adequate knowledge, IoT tools are underutilized, leading to suboptimal performance and missed opportunities for efficiency gains. Projects that attempt to integrate IoT without the necessary expertise often face implementation issues, causing delays and increased costs.

There is a significant shortage of skilled labor capable of working with advanced technologies. The construction industry is experiencing a talent gap, where the demand for tech-savvy professionals outstrips supply. Roles such as data analysts, IoT architects, and network engineers are critical for successful IoT integration. However, these specialists are in short supply and often prefer industries perceived as more technologically advanced. Many educational programs for construction management and engineering do not emphasize modern technological skills, leading to graduates who are unprepared for the demands of IoT-integrated construction sites. In some cases, skilled professionals may leave the construction industry for more lucrative or technologically progressive sectors, further depleting the talent pool. Construction firms face difficulties in recruiting and retaining skilled workers, leading to project delays and increased labor costs. A lack of skilled labor hampers the industry's ability to innovate and adopt new technologies, putting firms at a competitive disadvantage.

Traditional management practices are often resistant to change, making it difficult to adopt new technologies. Construction management is typically characterized by established routines and a hierarchical decision-making structure. Many construction managers prefer tried-and-tested methods and are skeptical of new technologies that disrupt conventional workflows. Effective IoT integration requires visionary leadership that can advocate for and manage change. In many cases, construction managers lack the strategic foresight to drive tech adoption. Implementing IoT technologies requires significant upfront investment in hardware, software, and training. Managers focused on short-term profitability may be reluctant to allocate resources to these areas. Management resistance leads to slow adoption rates of IoT technologies, causing firms to lag behind more progressive competitors. Without embracing new technologies, construction projects may suffer from inefficiencies and higher operational costs, impacting overall productivity.

Over-reliance on technology without proper understanding can lead to inefficiencies and errors. While IoT has the potential to significantly enhance construction processes, it is not a silver bullet and must be implemented thoughtfully. Without a clear understanding of IoT's capabilities and limitations, there is a risk of misapplying technology solutions, leading to inefficiencies. IoT systems require robust cybersecurity measures and reliable internet connectivity. Over-reliance on these systems without adequate safeguards can result in vulnerabilities and operational disruptions. IoT generates vast amounts of data, which can be overwhelming if not properly managed and analyzed. Firms without strong data management practices may struggle to extract actionable insights. Over-reliance on technology can expose construction projects to operational risks and potential failures. Missteps in technology implementation can lead to increased costs and project delays, undermining the potential benefits of IoT integration.

Addressing these barriers requires a multifaceted approach, including investment in education and training, strategic leadership, and a balanced approach to technology adoption. By overcoming these challenges, the construction industry in Malaysia and beyond can fully harness the potential of IoT to drive sustainable and efficient practices, contributing to the achievement of global sustainable development goals.

Addressing the Barriers- What’s Next?

To overcome the barriers to IoT integration in the construction industry, a multifaceted approach is required. This involves a combination of education and training, fostering a culture of innovation, and enhancing collaboration between key stakeholders. Below are detailed strategies for addressing these challenges:

1. Focus on Education and Training

2. Foster a Culture of Innovation and Adaptability

3. Enhance Collaboration Between Key Stakeholders

Addressing the barriers to IoT integration in the construction industry requires a concerted effort across multiple fronts. By focusing on education and training, fostering a culture of innovation, and enhancing collaboration between government, industry, and educational institutions, the construction industry can overcome these challenges and fully realize the benefits of IoT. This holistic approach will not only improve efficiency and productivity but also drive sustainable construction practices, contributing to the broader goals of sustainable development and resilience in the built environment.

Sustainable Development Goals (SDGs) and Construction

The integration of IoT technology and the emergence of the all construction performer are vital in advancing the construction industry's alignment with several Sustainable Development Goals (SDGs). These technological advancements and holistic approaches to construction are not only improving efficiency and productivity but also fostering sustainability, resilience, and inclusivity in the built environment. Below is a detailed examination of how these initiatives contribute to specific SDGs.

Promotes resilient infrastructure and sustainable industrialization.

a.Resilient Infrastructure:

b. Sustainable Industrialization:

Focuses on making cities inclusive, safe, resilient, and sustainable.

a. Inclusivity:

b. Safety:

c. Resilience and Sustainability:

Aims to ensure sustainable consumption and production patterns.

a. Sustainable Resource Use:

b. Efficient Production Processes:

c. Circular Economy:

By addressing the identified barriers and promoting the all construction performer model, Malaysia is making significant strides towards achieving these SDGs. The country's commitment to sustainable construction practices is setting a benchmark for other nations to follow.

The integration of IoT technology and the emergence of the all

construction performer model are pivotal in advancing sustainable

construction practices that align with the Sustainable Development

Goals. Malaysia's proactive approach in addressing barriers and

promoting these innovations sets a benchmark for other nations. By

continuing to invest in education, policy support, and industry

collaboration, Malaysia is well-positioned to lead the way in creating

resilient, inclusive, and sustainable built environments.

The emergence of the all construction performer in Malaysia represents a

significant advancement in the pursuit of sustainable construction. By

integrating various construction roles and leveraging IoT technology,

Malaysia is driving efficiency, reducing environmental impact, and

fostering innovation. This holistic approach not only addresses the

immediate challenges faced by the construction industry but also

contributes to the broader goals of sustainable development. As other

countries look to emulate Malaysia's success, the all construction

performer model offers a blueprint for a more sustainable and efficient

future in construction.